What is the Production Process of Mainstream Resistor Wiring Diagram?

I. Introduction

A. Definition of Resistors

Resistors are passive electronic components that limit the flow of electric current in a circuit. They are essential for controlling voltage and current levels, ensuring that electronic devices operate safely and effectively. Resistors come in various forms and materials, each designed for specific applications and performance characteristics.

B. Importance of Resistors in Electronic Circuits

In electronic circuits, resistors play a crucial role in managing current flow, dividing voltages, and protecting sensitive components from excessive current. They are fundamental in applications ranging from simple LED circuits to complex microprocessor systems. Without resistors, circuits would be prone to failure, leading to malfunctioning devices.

C. Overview of the Wiring Diagram

A wiring diagram is a visual representation of an electrical circuit, illustrating how components are connected. It serves as a blueprint for designing and troubleshooting circuits, making it easier for engineers and technicians to understand the relationships between different components, including resistors.

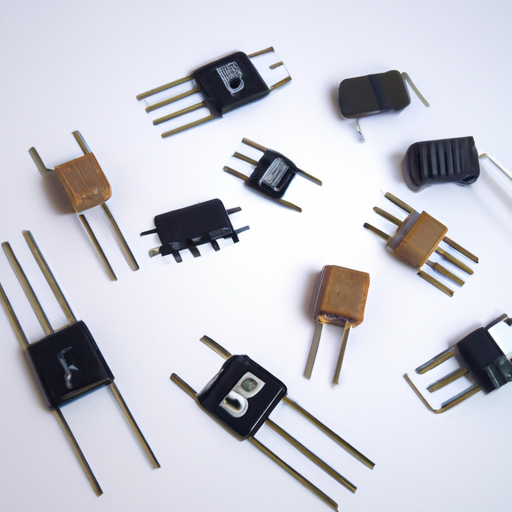

II. Types of Resistors

A. Fixed Resistors

Fixed resistors have a constant resistance value and are the most common type used in electronic circuits. They come in various materials and constructions:

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high tolerance and ability to withstand high temperatures. However, they are less stable than other types.

2. **Metal Film Resistors**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability and precision compared to carbon composition resistors, making them suitable for high-precision applications.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in power applications.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits.

1. **Potentiometers**: These are commonly used for volume control in audio equipment and can adjust resistance by turning a knob.

2. **Rheostats**: Similar to potentiometers but designed to handle higher currents, rheostats are often used in applications requiring variable resistance, such as in light dimmers.

C. Specialty Resistors

Specialty resistors are designed for specific applications and include:

1. **Thermistors**: Temperature-sensitive resistors that change resistance with temperature variations, commonly used in temperature sensing and control.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these change resistance based on light exposure, making them useful in light-sensing applications.

III. Understanding Resistor Wiring Diagrams

A. Components of a Wiring Diagram

A wiring diagram consists of various components that represent the electrical circuit:

1. **Symbols and Notations**: Each component in a circuit is represented by a specific symbol, such as zigzag lines for resistors. Understanding these symbols is crucial for interpreting diagrams accurately.

2. **Circuit Layout**: The layout shows how components are interconnected, providing a clear visual representation of the circuit's structure.

B. Importance of Wiring Diagrams in Circuit Design

Wiring diagrams are essential for circuit design and troubleshooting. They help engineers visualize the circuit, identify potential issues, and ensure that components are connected correctly. A well-documented wiring diagram can save time and resources during the design and testing phases.

C. Common Applications of Resistor Wiring Diagrams

Resistor wiring diagrams are used in various applications, including:

Consumer Electronics: Designing circuits for devices like televisions, radios, and smartphones.

Industrial Equipment: Creating control systems for machinery and automation.

Educational Purposes: Teaching students about circuit design and electronics.

IV. The Production Process of Resistors

A. Material Selection

The production of resistors begins with careful material selection:

1. **Conductive Materials**: The choice of conductive materials, such as carbon, metal films, or wire, affects the resistor's performance characteristics, including resistance value and power rating.

2. **Insulating Materials**: Insulating materials, such as ceramics or plastics, are used to encase the resistive element, ensuring safety and stability in various environments.

B. Manufacturing Techniques

Different types of resistors require specific manufacturing techniques:

1. **Film Resistor Production**:

a. **Substrate Preparation**: A ceramic substrate is prepared to provide a stable base for the resistive layer.

b. **Thin Film Deposition**: A thin layer of resistive material is deposited onto the substrate using techniques like sputtering or chemical vapor deposition.

c. **Laser Trimming**: The resistance value is fine-tuned using laser trimming, which removes material to achieve the desired resistance.

2. **Wirewound Resistor Production**:

a. **Wire Selection**: High-quality metal wire is selected based on the desired resistance and power rating.

b. **Winding Process**: The wire is wound around a core, creating the resistive element.

c. **Encapsulation**: The wound resistor is encapsulated in a protective material to ensure durability and reliability.

3. **Carbon Composition Resistor Production**:

a. **Mixture Preparation**: A mixture of carbon and binding agents is prepared to create the resistive element.

b. **Molding and Curing**: The mixture is molded into the desired shape and cured to harden the material.

C. Quality Control Measures

Quality control is critical in resistor production to ensure reliability and performance:

1. **Testing for Resistance Values**: Each resistor is tested to verify that it meets specified resistance values and tolerances.

2. **Environmental Testing**: Resistors undergo environmental testing to assess their performance under various conditions, such as temperature and humidity.

3. **Reliability Testing**: Long-term reliability tests are conducted to ensure that resistors maintain their performance over time.

V. Creating a Resistor Wiring Diagram

A. Tools and Software for Diagram Creation

Creating a resistor wiring diagram requires specific tools and software. Popular options include:

CAD Software: Programs like AutoCAD and Eagle are widely used for designing electronic circuits.

Online Diagram Tools: Websites like Lucidchart and Draw.io offer user-friendly interfaces for creating wiring diagrams.

B. Step-by-Step Process

1. **Identifying Components**: Begin by listing all components, including resistors, capacitors, and power sources.

2. **Designing the Layout**: Arrange components logically, ensuring that connections are clear and easy to follow.

3. **Adding Symbols and Notations**: Use standard symbols to represent each component, and include notations for values and specifications.

C. Best Practices for Clarity and Accuracy

To ensure clarity and accuracy in wiring diagrams:

- Use consistent symbols and notations throughout the diagram.

- Keep the layout organized and avoid crossing lines whenever possible.

- Label all components clearly, including resistance values and tolerances.

VI. Conclusion

A. Recap of the Importance of Resistors and Wiring Diagrams

Resistors are fundamental components in electronic circuits, playing a vital role in controlling current and voltage. Wiring diagrams are essential tools for designing and troubleshooting circuits, providing a clear visual representation of how components are interconnected.

B. Future Trends in Resistor Technology

As technology advances, resistor technology continues to evolve. Innovations in materials and manufacturing processes are leading to more efficient, reliable, and compact resistors. Additionally, the integration of smart technologies may pave the way for adaptive resistors that can adjust their values based on circuit conditions.

C. Final Thoughts on the Production Process and Its Relevance in Electronics

Understanding the production process of resistors and the creation of wiring diagrams is crucial for anyone involved in electronics. As devices become more complex, the need for precise and reliable components will only grow, making the knowledge of resistors and their applications more relevant than ever.

VII. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Electronic Materials

B. Industry Standards

- International Electrotechnical Commission (IEC) Standards

- American National Standards Institute (ANSI) Standards

C. Online Resources and Tutorials

- Electronics Tutorials (www.electronicstutorials.com)

- All About Circuits (www.allaboutcircuits.com)

This comprehensive overview of the production process of mainstream resistor wiring diagrams provides valuable insights into the importance of resistors in electronics, their types, and the steps involved in creating effective wiring diagrams. Understanding these concepts is essential for anyone looking to deepen their knowledge of electronic circuit design and manufacturing.