NEW

dict2_description

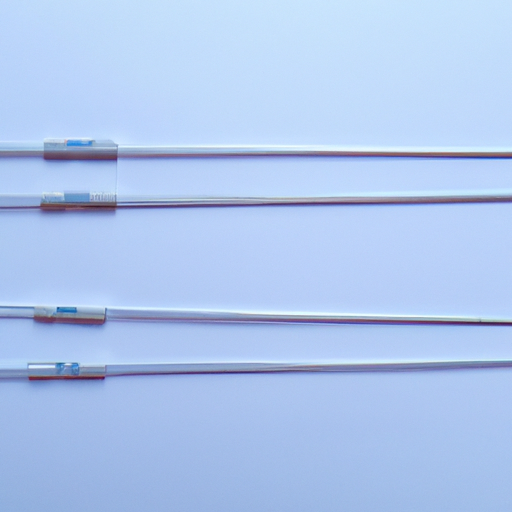

What is the production process of mainstream resistor 4?

2024-11-08

13

What are the popular models of resistor packages?

2024-11-07

10

What are the product features of Resistor 3?

2024-11-06

12